Encompass Response to Coronavirus

Updated April 21, 2020

Message from Encompass President & CEO Robert Coolidge

Encompass has been closely monitoring the global impact of the coronavirus (COVID-19) pandemic since it first originated in China. Our heartfelt condolences are with all those who have been sickened and died from this terrible illness. Please click here for a helpful pamphlet on Preventing the Spread of Respiratory Diseases from the Center for Disease Control and Prevention.

Internal Response

Internal Response

Although all Encompass facilities are operating regular schedules, we have taken several precautions for the health and well-being of both our associates and business partners. We are following all government guidance and mandates to help contain the pandemic. Some measures we have taken include:

- Office staff are telecommuting until further notice. Encompass is equipped with cloud-based systems, ensuring continuous communications both internally and with our customers.

- Essential on-site staff are required to wear masks and gloves and are also being provided antiseptic wipes and hand sanitizer at work stations and common areas. More importantly, they are mandated to frequently wash hands.

- Staff travel is restricted.

Parts Supply Continuity

Due to the expected closings of factories during the January Chinese New Year, our Purchasing team had procured safety stock for the select brands for which we source directly overseas. At this time, highest demand parts remain in stock across multiple product verticals, including Home Appliance and Consumer Electronics. However, the team is in daily contact with manufacturers to identify any supply disruptions so we can then communicate with our customers.

Encompass has no immediate plans to close facilities and will continue to follow standard preventative guidelines to address the current situation.

Counter Sales Reopened

With additional safety measures in place, counter sales/order pickup has resumed at all locations. The counters at our Atlanta, Fort Lauderdale and Las Vegas distribution centers will be open Monday-Friday, 8:30am-4pm. To limit contact, we request that customers first place orders on encompass.com prior to coming to the facility, if possible.

Help for Customers

Encompass is here for you! If we can be of any assistance, please let us know: customercare@encompass.com. Have you taken advantage of the Coronavirus Aid, Relief, and Economic Security Act (CARES)? CARES enables small businesses and contract workers to obtain a variety of loans to maintain operations and prevent layoffs during this unprecedented crisis. Tax advantages are also available.

We appreciate your patience and understanding during this difficult time. Encompass will continue to update this company response statement as conditions warrant to keep you informed.

Robert Coolidge

President & CEO

Open Top

Open Top

To comply with individual state sales tax regulations, Encompass must collect sales tax certificates for each state in which your business is exempt and to which you have part orders shipped. The deadline to submit your current certificate to Encompass has been extended to

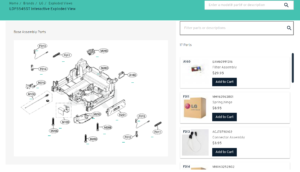

To comply with individual state sales tax regulations, Encompass must collect sales tax certificates for each state in which your business is exempt and to which you have part orders shipped. The deadline to submit your current certificate to Encompass has been extended to Remove Broken Dryer Buzzer — Take off the buzzer knob or button. Trace the button to the exact location in the back of the dryer. Different dryer models often place the buzzer in various locations, so this is the most reliable way to find the right part. You can also match it to the appearance of your replacement part.

Remove Broken Dryer Buzzer — Take off the buzzer knob or button. Trace the button to the exact location in the back of the dryer. Different dryer models often place the buzzer in various locations, so this is the most reliable way to find the right part. You can also match it to the appearance of your replacement part.