To repair or replace is one of the greatest quandaries regularly affecting the reverse logistics industry. Consumers are inundated with various formulas and advice on whether to repair the refrigerator that’s not cooling or the dryer that’s not heating – or upgrade to the latest model.

When the economy is flourishing, consumers tend to lean toward replacement. Their existing model suddenly seems obsolete when a flashier version hits the market, especially if the current unit is not functioning properly.

The most common rule of thumb is to opt for repair if the cost is less than 50% of the new purchase price. Underwriters follow a similar rule when determining whether to replace or repair a product  under warranty. However, while financial considerations are certainly high priority, some businesses and consumers also place value on eco-friendly solutions to minimize the harmful impact of e-waste.

under warranty. However, while financial considerations are certainly high priority, some businesses and consumers also place value on eco-friendly solutions to minimize the harmful impact of e-waste.

SourceToday reports that more than 40 million tons of e-waste are annually generated worldwide. By the year 2050, global e-waste production could reach 120 million tons annually if current trends continue. According to The World Health Organization (WHO), e-waste emits numerous toxic materials such as lead, cadmium, chromium, brominated flame retardants and polychlorinated biphenyls (PCBs). Humans get exposure to these toxins by inhaling fumes, as well as from accumulation of chemicals in soil, water and food.

Right to Repair

The service repair industry is currently benefiting from “right to repair” efforts at both the state and federal levels. Groups pushing to maximize repair opportunities claim some manufacturers make it nearly impossible to fix their goods so they can sell new products instead.

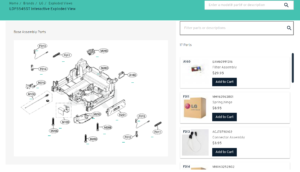

Proposed legislation typically requires manufacturers to provide service manuals and diagnostic software, as well as make replacement parts available to increase repair capabilities for DIY consumers and professional service techs alike. New laws are intended to both prevent e-waste and increase competition among repair providers.

Industry Developments

To meet demand, the repair industry continues to improve with new technology and operational processes. Some repair depots have employed advanced test equipment that passively tests circuit boards to determine out-of-tolerance conditions. This enables more detailed troubleshooting and helps make repairs more viable since costly, often hard-to-find test fixtures aren’t needed.

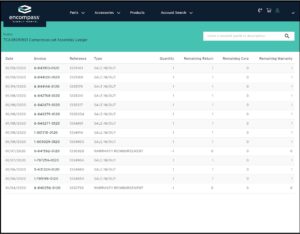

With software enhancements delivering real-time tracking throughout the repair cycle, automated status updates can be provided to keep customers/end users informed – minimizing time-consuming calls and update requests.

Repair Challenges and Solutions

Repair providers are not without their own unique challenges. They are constantly under pressure to reduce turn times and increase yield within constraints of shipping time and expense. They often have to compete against depots offering cheap flat rate pricing regardless of labor and part costs.

Additionally, not all repairs are equal. While some only require fast, less expensive “fluff and buff” service, others are much more complex, requiring additional time, effort and pricey components.

To combat these common issues, many depots have found creative ways to keep costs down to enable more economical repairs. Using parts harvested from non-repairable products is one way to offset costs of high-dollar components like circuit boards. Repairing such boards is also critical to maintaining a strong parts supply chain to increase repairs.

To simplify shipping to depot facilities, service providers are often partnering with freight carriers to offer convenient product drop off and pick up locations. Continually reviewing and negotiating favorable freight rates is another important way to control costs and help make repairs more financially feasible.

Assessing Repair Partners

There are several key factors to consider when selecting a repair partner. First, prior to engagement, it’s critical to outline specific services required, performance expectations and business rules. One of the most important aspects of this process includes determining the economical price point for repair, plus product disposition options when the maximum is exceeded.

Establishing metrics for repair yield, cost, turnaround time, quality and other indicators are necessary to adequately evaluate performance. Depots should be able to document each step of the repair process for accountability and then deliver extensive reporting to gauge performance. By measuring all facets of the repair operation, depots should be striving to continually improve and meet or exceed service level expectations.

Position for Success

With both strong financial and environmental cases to be made for repair, momentum is growing on the side of repair providers. Those leveraging new technology, highly-efficient practices and strategic pricing will be best positioned to take advantage of right to repair laws and succeed against competitors.

Internal Response

Internal Response To comply with individual state sales tax regulations, Encompass must collect sales tax certificates for each state in which your business is exempt and to which you have part orders shipped. The deadline to submit your current certificate to Encompass has been extended to

To comply with individual state sales tax regulations, Encompass must collect sales tax certificates for each state in which your business is exempt and to which you have part orders shipped. The deadline to submit your current certificate to Encompass has been extended to

A major cleaning should be done at least a couple of months before the holidays whether you’re using the self-cleaning function or regular spray cleaner. Cleaners can leave harsh residues that can take some time to dissipate.

A major cleaning should be done at least a couple of months before the holidays whether you’re using the self-cleaning function or regular spray cleaner. Cleaners can leave harsh residues that can take some time to dissipate.

under warranty. However, while financial considerations are certainly high priority, some businesses and consumers also place value on eco-friendly solutions to minimize the harmful impact of e-waste.

under warranty. However, while financial considerations are certainly high priority, some businesses and consumers also place value on eco-friendly solutions to minimize the harmful impact of e-waste.