CE Tech Tips — February 2018

**NOTICE**

Due the danger and complexity of electronics repair, the following shared technical tips are intended for professional reference only. Please refer to manufacturer’s recommendations as Encompass does not guarantee the accuracy, reliability or safety of this information.

Audiovox TV, FPE3206

Reason for Service: No audio

Solution: Found SM cap C210 bad, and had leaked on board. Clean board thoroughly in the surrounding area.

Hitachi TV, 50V500A

Reason for Service: No video with sync bars, or aspect not working.

Solution: These symptoms are caused by problems with the PSC3 (50 pin) connector, on either end, or with the ribbon cable #EK01182.

Magnavox TV, 26MF330B/F7

Reason for Service: Dead

Solution: Found shorted cap, C645 in power supply. 3300uF/6.3V

Mitsubishi TV, VS-583R

Reason for Service: Convergence not working

Solution: Replaced the following to fix set: STK392-110’s, R520 & R522, 0.82ohm/2W, & D520 & 522

Sharp TV, LC-60E69U

Reason for Service: Dead

Solution: Found 3 open resistors in power supply. One meg each. Replacing, fixed the set.

Sony TV, KLV26HG2

Reason for Service: Won’t power up, no lights on front panel.

Solution: Replacing the B board fixed the set.

Toshiba TV, MW26G71

Reason for Service: Shutdown

Solution: Flyback, FB401 found to be defective. Replaced with AE004955.

Vizio TV, VX20LHDTV

Reason for Service: Won’t start

Solution: When turning set on, logo was amber but never turned to white. Replacing U8 fixed the set. AMC1117 regulator.

3. Isolate the temperature control. First, remove the knob from the shaft in the back right corner with a screwdriver. Then, pry the tabs connecting the grounding and adjacent wires free.

3. Isolate the temperature control. First, remove the knob from the shaft in the back right corner with a screwdriver. Then, pry the tabs connecting the grounding and adjacent wires free.

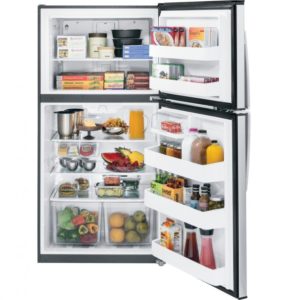

How to Replace Refrigerator Door Switch

How to Replace Refrigerator Door Switch