Encompass Supply Chain Solutions, Inc.

From Tire Store to Market Leader in Forward and Reverse Logistics in 65 Years

What began as a small family-operated tire and appliance venture in Miami has evolved over six decades to become one of the largest, most diversified repair parts and supply chain service companies in the U.S.

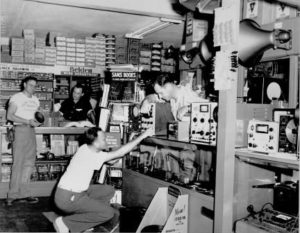

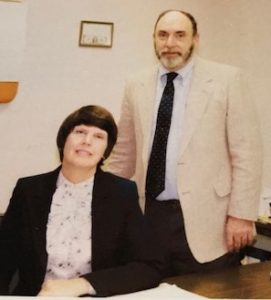

Vance Baldwin Electronics (c. 1953). Founder Vance Baldwin at left with General Manager Hank Politz

Encompass was originally formed in 1953 as Vance Baldwin Electronics in Ft. Lauderdale, Fla. Baldwin, the company’s namesake and founder, is the maternal grandfather of Encompass’ current president and CEO, Robert Coolidge. In the mid-2000s, Vance Baldwin, along with Tritronics (parts distributor based in the Northeast) and Cyber-Test (Central Florida repair service business) were acquired and merged together to form Encompass.

The Early Days

In the 1940s, Baldwin sold tires and appliances for BF Goodrich, as well as refrigerators and furniture for Kmart in South Florida. He then opened his own business, Economy Auto Tire, which offered both tires and small appliances. In those days, no businesses

were dedicated to just appliances, thus the odd combination of goods.

Baldwin leased space in his store to Ned Goddard who repaired radios. Seeking to capitalize on an opportunity in radio and television tubes, the pair opened Goddard Supply in 1950 in West Palm Beach, Fla. as a side business. With its success, they opened another in Ft. Lauderdale the following year.

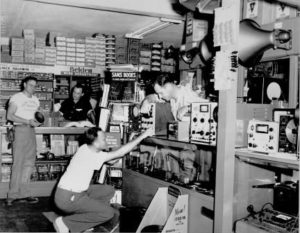

Vance Baldwin Electronics (c. 1955)

Baldwin split with Goddard in 1953 and renamed the Ft. Lauderdale business Vance Baldwin Electronics. The store carried TV tubes, public address speakers, phonograph needles, TV wire, cable and antennas. Baldwin handled purchasing and finance and hired a salesman to call on area TV repair shops. Deliveries were made the next day in company vans.

In 1960, Baldwin converted the Economy Auto Tire store to a third branch of Vance Baldwin Electronics. At the height of the business, Baldwin had a store in Fort Lauderdale, Miami, West Palm Beach and Tampa.

Surviving Industry Changes and Competition

In the 1960s and 1970s, competition from big box stores started creeping in, but the electronics industry was still just emerging. In 1973, Baldwin’s son Fred joined the business as a salesman for the Miami branch after graduating from Florida State University. The store was struggling at the time to compete against other local businesses. TV tubes represented the majority of store sales. They were generic and could fit multiple manufacturer brands. As a result, the only way to really differentiate in the market was through price.

Fred Baldwin soon landed the coveted Channel Master line of popular antennas, another product with high demand before cable took off

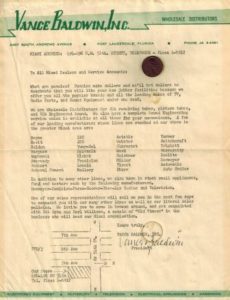

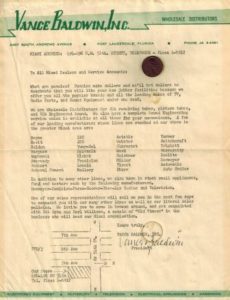

Vance Baldwin Electronics’ first line card

– particularly after frequent Florida rain storms. As transistors started coming out to revolutionize electronics, the supplier became one of the first RCA original parts distributors.

With television tubes, just about anyone could repair a TV, but with sets now becoming more sophisticated and circuit board-based, servicers had to ramp up their technical skills. This shift also changed the dynamics of the parts distribution business since boards, unlike tubes, were unique to each manufacturer. Vance Baldwin had locked in exclusive distribution agreements with numerous electronics manufacturers, so many other distributors were forced to switch to other market segments, such as industrial parts.

With the competition Vance Baldwin did face, the main way to stand apart was having parts on the shelf, readily available, versus price. The company also offered same or next day delivery, will call / counter sales and a showroom that featured test equipment, solder, tools and other items. They marketed the business through monthly flyers and a product catalog mass distributed to TV repair shops.

In 1980, Vance Baldwin’s Miami location was set on fire during the infamous Liberty City riots. Looters had spied boxes of parts and mistook them for valuable electronics. The street in front of the store was littered with discarded boxes and scattered parts. The company was forced to relocate to another area of Miami and in 1983, opened a facility in Tampa, adding to existing facilities in Ft. Lauderdale and West Palm Beach. Fred was named company president at this time.

No-Tech Warehousing and Fulfillment

Tampa VBE facility — delivery van at left (c. 1984)

In Tampa, Scott Cameron was hired as the first deliveryman for the business, working his way up to branch manager. Today, he is senior vice president of Operations and Service Solutions for Encompass. Tom LoCrasto, who joined the Tampa branch as a salesman about the same time as Scott in 1983, is also still a member of the Encompass team, serving as an account manager for key clients.

Tom traveled the state calling on small “mom and pop” electronics repair stores sharing printed catalogs that listed Vance Baldwin’s brands and high-demand parts. In the early 1980s, cable TV had not yet penetrated rural areas, so antennas remained a hot item, especially during notorious Florida thunderstorms when high winds could send them flying off roofs.

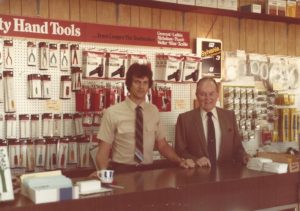

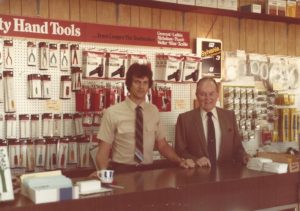

Fred Baldwin (left) with Vance Baldwin at Tampa facility (c. 1984)

Tom would then stop by phone booths to call in orders to the Tampa warehouse, which he would then often pick up and deliver himself on his next visit to the customer. Everything was done manually – from handwriting pick tickets and invoices to counting physical inventory.

Vance Baldwin stayed active in the business, working primarily in accounting, before retiring in the mid-1980s. In 1990, Fred recruited his nephew, Robert Coolidge, to lead IT efforts for the company. A computer at that time was only used for financial functions. Everything else, including inventory procedures, was done manually on paper. Printed catalogs and line cards were a must-have for marketing purposes.

To check to see if a part was available, employees had to physically count inventory cards. Orders were similarly taken down on paper, and if a part was on back order, an employee had to call and inform a customer. Because manufacturers resisted fulfilling orders daily like they do now, most parts came in on stock orders, and it took much longer to fill back orders. If Vance Baldwin didn’t have a part, they would typically just lose the sale.

Entering the Digital Age

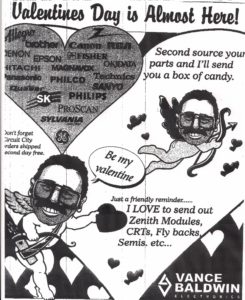

Tampa store’s Valentine’s Day promotion featuring salesman Tom LoCrasto as cupid (1999)

To increase efficiency, Fred and Robert evaluated various software systems and eventually purchased a system and source code. Robert was trained in writing code, so they could manage the system on their own without having to rely on outside vendors. Leveraging this added capability, Robert sold the concept and value of system integration to various retailers such as Circuit City and Rent-A-Center.

As one of the first major innovations for the company, Vance Baldwin could now accept orders electronically and report to clients what had shipped that day – something that gave the company an edge over competitors. Robert touted tech services to land larger and larger clients with national scope, as well as new manufacturer brands sold by these clients.

The system was based on software used in the automotive industry to manage core parts. The concept of putting a “return deposit” or core on high demand, expensive parts like circuit boards initiated in the auto space and later into electronics with Vance Baldwin at the forefront. Robert used his tech savvy to reconfigure and customize the software to better fit the business and client needs.

By the late 1990s and early 2000s, the company started phasing out printed catalogs to focus solely on e-commerce. While sales were made through the web, manufacturer referrals were more of a sales driver. Vance Baldwin also started offering web hosting for businesses such as remote control suppliers. During this time, Robert

Former Vance Baldwin Electronics President Fred Baldwin (2012)

and Scott were instrumental in automating the warehouse and improving the pick/pack/ship process to be more streamlined and productive.

Seeking a more centralized location to serve its nationwide customer base, Fred decided to close the Tampa facility in 2001 and open a larger distribution center in Lawrenceville, GA. The facility was strategically situated just north of Atlanta, a transportation super hub.

By the mid-2000s, TV failure rates – and prices – began dropping rapidly, and LCD televisions were starting to replace DLP. DLP lamps were one of the company’s top-selling parts because they needed to be regularly replaced, so this had a serious impact on sales. Plus, manufacturers that had primarily relied on distributors to supply parts, increasingly began selling direct to capture additional revenue.

It was in this market climate in 2007 when Fred decided the time was right to exit the business. He sold the company to Encompass Group Affiliates, the principal operating unit of Advanced Communications Technology, Inc., a New York-based company, which publicly-traded the new business “over-the-counter.”

Encompass had already acquired Cyber-Test, a Florida-based electronics repair business. After the Vance Baldwin acquisition, Encompass acquired Tritronics, another industry-leading parts supplier with distribution centers in Maryland and South Florida. Most of the leadership from the merged companies remained intact to manage day-to-day operations and business development efforts.

Loyalty is Foundation of Tritronics Formation

Roger Williams’ foresight and sense of loyalty led to the founding of Tritronics in 1975. While working as a sales rep for an electronics

First Tritronics building outside Baltimore

distributor in Baltimore, Md., he was told to fire the manager who initially hired him. The business was floundering, and Roger was the top salesperson, so the owner had planned to increase his pay after the manager was let go. Instead, predicting (correctly) that the company was going under – and not willing to terminate his own manager – Roger convinced his manager and another co-worker to instead leave with him and form their own company. His wife Ginny thought up the name “Tritronics,” to symbolize the trio engaging in the electronics industry. Roger and his partners were ready for business.

For their first storefront, the triumvirate rented the ground floor of a former grocery store and meat market in Perry Hall just outside Baltimore. The space was about 2,200 square feet; within six months they took over the entire

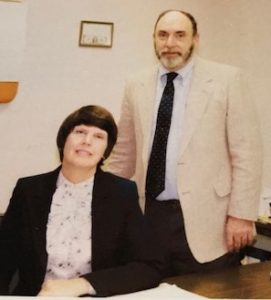

Tritronics Founders/Owners Roger & Ginny Williams during visit to Abingdon, MD facility (1985)

5,000-square-foot building. They were a Channel Master distributor and sold a variety of television parts, operating out of the space – which they ultimately purchased – until 1981.

Adapting to Industry Trends

By 1982, the company principals predicted that receiving tubes were soon going to be obsolete. Like Vance Baldwin, they were keenly

aware that the industry was changing with more and more manufacturers requiring original parts for repairs. Tritronics obtained their first major line of direct replacement parts to support GE followed by RCA. The company next went after Sharp, which was then looking for 20 distributors across the U.S. to provide parts support. Sharp, along with other manufacturers, required Tritronics to have a QUIP machine – a precursor to the fax machine – for order transmission, which they had obtained.

Two Sharp representatives met with Roger as part of their search. When told of the volume he could expect as a national distributor for Sharp, his “mouth was hanging on the floor.” The reps left and told him they’d be in touch soon with their decision. Not willing to wait, Roger drove the next day from Baltimore to the Sharp facility in New Jersey and caught the men as they were coming into work. He asked them “Where do

Tritronics team at Abingdon, MD facility. Photo shot for parts catalog.

I sign? We’re ready to start now.” Flabbergasted, they told Roger they had not yet made a decision since they only just met with him the previous day. Unfazed, Roger insisted “There’s no time like the present,” and the reps finally conceded. Much later in the relationship, the leader of Sharp parts and service told Roger, “I don’t know what you’re doing down there, but keep it up.”

All of this marked a huge turning point for the company, which was still operating out of old meat market with two upstairs apartments. To accommodate their growth, they moved the business to Columbia, MD located between Washington, D.C. and Baltimore, which was easier to ship to with a direct path to manufacturer proprietary parts. The new facility was 5,000 square feet with one level. At that point, the business was joined by two of the Williams’ children, Kim Wagner and Randy Williams, and a son-in-law, Jim Scarff. [Kim served the company until 2012 as head of Operations. Randy remains with the company today as vice president of Purchasing and Jim as vice president of Customer Support.]

Every step of the pick/pack/ship process was done manually at the time. Servicers would call in to order a part, and an employee would look up the model’s exploded view in a service manual, search the parts list for the part number and then find the price in another manual or via microfiche. This process took 5-10 minutes; now this information is just a click away on the Internet.

Automating the Business

By 1985, Roger was ready to invest in a computer system to automate many of the business’ manual tasks. The remaining partner then

Tritronics in age of CRTs and dot matrix printers

decided the time was right to leave the company. With no prior business experience, Ginny stepped up to become Tritronics’ “computer whiz,” maintaining two systems to separately manage inventory and accounts receivable.

In 1988, the couple developed their own 20,000-square-foot building in Abingdon, MD. The timing couldn’t have been better because Sharp was cutting its 20-distributor network to just three. With an impressive new distribution center, Tritronics was fortunate to become one of those three. Soon after, Roger seized on another Sharp opportunity by opening a second facility in Miami to serve the Southeastern U.S. This new distribution center was also convenient for customers who were flying into South Florida from the Caribbean islands just to buy repair parts.

Over the years, Tritronics carved a niche as a distributor focused on serving the smaller repair shops, while competitors like Vance Baldwin were seeking to partner with large retailers. Fast forward to 2007: Tritronics’ Abingdon facility had grown to more than 42,000 square feet, served around 5,000 active customers and employed 85 staff members. The television market was changing drastically, and Tritronics was starting to feel the effects. New unit prices were dropping so low that it was becoming more economical to replace a set than repair one, so once profitable parts were no longer in heavy demand.

Time to Exit

Just like Fred Baldwin, Roger decided the time was right to accept a purchase offer extended by Encompass Group Affiliates, Inc. (EGA),

Encompass headquarters in Lawrenceville, GA

a New York-based publicly-held company. In 2004, EGA acquired Cyber-Test, an electronics equipment repair company. By completing the acquisition of both Vance Baldwin and Tritronics in 2007, EGA became one of the only distributors in the country offering both repair service and parts under one roof. Cyber-Test was rebranded to Encompass Service Solutions, and Vance Baldwin and Tritronics were united under the name Encompass Parts Distribution.

During the economic decline of the late 2000s and early 2010s, the company reorganized. In 2011, the company went private as Encompass Supply Chain Solutions, Inc., and Robert Coolidge was named President and CEO. A salesman at heart, Robert has proven to be a hands-on executive who aggressively seeks new business opportunities wherever they may lie. He is never content with the status quo and persistently challenges his team to think creatively and push the boundaries. This drive has helped steer Encompass through some of the most challenging times of its six-decade history, and has helped positioned the company for continued success and profitability.

Robert Coolidge

Encompass President & CEO

Robert has been able to accurately predict market trends, which led the company to start diversifying parts support years ago to prevent too much reliance on consumer electronics. The CE industry is now faced with changing technology combined with falling prices, making obsolescence a constant battle. In years past, when TVs were much more expensive, consumers usually had them repaired. Now they want the latest models, and it’s no longer as cost-prohibitive to simply throw out non-working sets.

Celebrating 65 Years

Encompass has grown tremendously and now supports more than 200 manufacturer brands in dozens of product categories beyond consumer electronics – from personal care to home maintenance. More manufacturers are opting to outsource their entire parts supply chain to control infrastructure and labor costs, while improving customer satisfaction. Managing the parts supply chain has become a key offering from Encompass, which counts among its clients global manufacturers such as Sony, Panasonic and Philips.

Encompass adds automated conveyor to increase productivity (2014)

As it reaches its 65th anniversary, Encompass’ core business still centers on parts distribution, but it has significantly expanded to offer a full range of both forward and reverse logistics services. Now shipping parts worldwide, Encompass continues to operate facilities in South Florida and Atlanta and recently expanded to Las Vegas. The company also targets new customer segments like consumers and whole home warranty providers. With so many diverse product verticals supported, Encompass is an ideal partner for warranty companies covering a range of different goods.

Vance Baldwin may not recognize the company he first founded, but he would be proud that the foundation he laid remains solid – there have just been a few renovations and extra stories added on with more exciting enhancements on the horizon for years to come.

pressure settings. That means there are multiple different triggers that could force the pump and motor assembly to break.

pressure settings. That means there are multiple different triggers that could force the pump and motor assembly to break.

particles away. Here’s how to fix a Whirlpool dishwasher in just a few minutes with replacement part

particles away. Here’s how to fix a Whirlpool dishwasher in just a few minutes with replacement part  3. Isolate the temperature control. First, remove the knob from the shaft in the back right corner with a screwdriver. Then, pry the tabs connecting the grounding and adjacent wires free.

3. Isolate the temperature control. First, remove the knob from the shaft in the back right corner with a screwdriver. Then, pry the tabs connecting the grounding and adjacent wires free.