Is your business listed accurately online? Here’s why it’s so important.

In today’s virtual world, search engines have replaced the Yellow Pages as the #1 tool consumers use to find anything they need, from driveway paving to washer repair. Developing a dynamic business website is important, but ensuring your company is accurately listed on various other online channels is just as critical. These online directories or “citations” are any sites that post a company’s name, physical address, phone number and web address.

Some examples of citation sites are Google My Business, Yelp, Facebook, Foursquare, Merchant Circle, CitySearch and Bing Places, among others. Like the phone books of days past, businesses must ensure their listings are correct with updated information. Companies often set up their profiles and never look at them again. However, the Internet is a dynamic entity — it moves and changes like the wind.

A simple mistake can occur like it did recently with Fred’s Appliance Service. A DSL (Internet connection) number ended up being listed by accident to multiple online directories. The DSL number would ring forever with no answer. An unintended error by the DSL provider caused major issues for Fred’s Service. Customers would call for hours with no luck assuming the company was closed, and they took their business elsewhere. Unlike today’s high-tech appliances, there is no error code for this type of blunder. The damage is hard to calculate since Fred’s had no idea how long the issue had been going on and how many people tried to call the wrong number.

Sometimes errors may be more intentional. Take this recent news story of a customer calling the number on a Google listing only to have someone pose as a company representative. It wasn’t until the customer found a different number listed on a different website that she discovered the issue. The company owner had not been checking his company listings, enabling others to siphon customers away while damaging his reputation in the process.

Ensuring your customers have the right information is important, but it’s also important to look through search engines like Google and Bing. Just because you have a Google My Business listing does not mean you will show up in Google search results when someone enters “appliance repair near me.” Search engines pull from all citation sites to narrow down the best results to search queries. So having your business listed on as many citation sites as possible will help increase your online exposure.

To check your business’ online profile, start by taking time to review listings at Google My Business, Bing Places, Facebook and Yelp. Make sure the correct data is provided, including your hours of operation (including holiday hours). It can be overwhelming and time consuming to maintain all your listings, so consider partnering with a marketing company like Fluid Services, which can help update listings and provide regular reports of the most common directories. This will give you peace-of-mind knowing that your customers are going to consistently find the most accurate contact information for your company.

Special thanks to Fred’s Appliance Academy for this helpful tip!

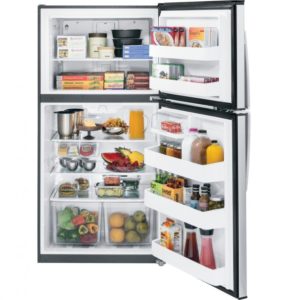

How to Replace Refrigerator Door Switch

How to Replace Refrigerator Door Switch

How to Troubleshoot Your Whirlpool Ice Make

How to Troubleshoot Your Whirlpool Ice Make Safety First

Safety First